High quality fibrillation technology for dry electrode

Through simulation analysis of particle size and density of different materials, High Energy Numerical Manufacturing has developed different blades that are suitable for different materials, ensuring strong shear force during high-speed rotation. Through precise temperature control of the equipment, the adhesive is ensured to be in the appropriate temperature range for fiberization, achieving the maximum degree of material fibrillation. At the same time, fiber network reinforcement equipment can further improve the effectiveness and strength of fibrosis, increase the mechanical properties and production efficiency of the polarizer. Continuous production equipment and process flow can meet the high-quality mass production of dry electrodes.

High quality dry electrode film composite technology

Gaoneng Shuzao has independently developed an automated continuous feeding equipment, which, combined with multi-stage differential rollers, can achieve integrated film making and thinning operations, reducing equipment and site investment. Multi level continuous thinning steps, the equipment can output polarizer with high uniformity in thickness and surface density. By using a large tonnage rolling composite machine, coupled with high-precision correction and thickness sensors, the double-sided composite of film material and current collector is achieved, and the surface density of dry polarizer is further improved.

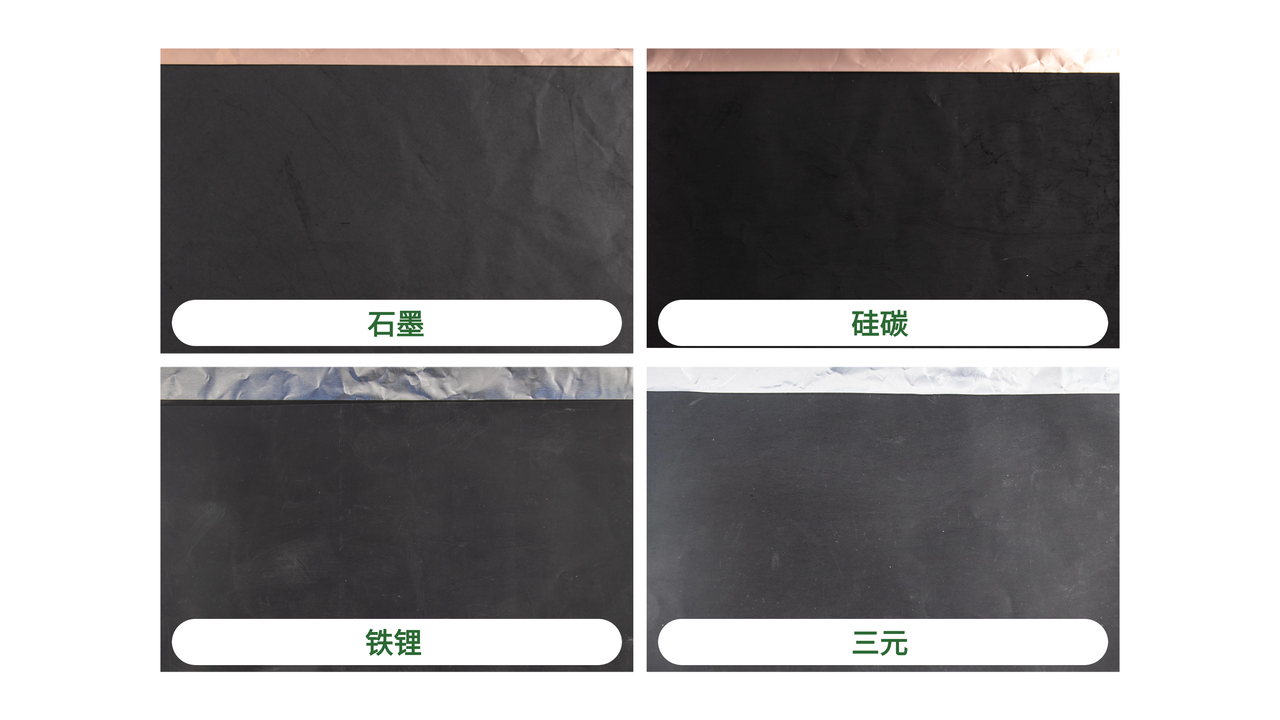

Reserve of various dry electrode specialized material systems

In terms of binders, High Energy Numerical Manufacturing and Daikin Fluorochemicals have collaborated deeply to develop a binder solution that can improve the tensile strength of electrode sheets and optimize negative electrode applications.

In terms of current collectors, high-energy data processing uses dry specialized current collectors, which can effectively increase the adhesion force of self-supporting membranes and improve the peeling strength of polar plates.

In terms of conductive agents, High Energy Digital Manufacturing has collaborated deeply with the National Graphene Center to develop efficient conductive agents for dry process technology, improve electrode conductivity, and achieve better mechanical properties.

Lithium metal all-solid-state battery small test line the whole line equipment acceptance

2024-10-12Recently, High-energy Digital Manufacturing has completed the formal delivery of another lithium metal all-solid-state ba…The small dry test line of high energy all-solid state battery is officially launched

2024-10-12At present, the all-solid-state battery that has attracted much attention is at a high speed of development and has recei…High energy production of lithium metal all-solid-state battery pilot line

2024-10-12High automation, high precision and high efficiency of the high-precision lithium metal all-solid state battery pilot lin…High energy manufacturing main business

2024-10-12➣Battery 3D printing system equipment: Innovative battery preparation process, through the battery 3D printer to achieve…