Solution for manufacturing solid-state batteries using a combination of dry and wet methods

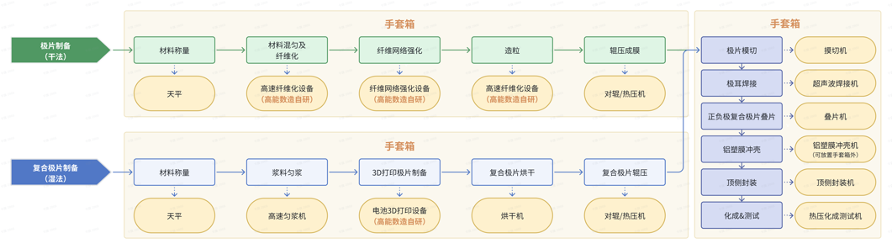

• Dry process: With high-speed mixing and shearing machines and film-forming composite machines as the core, combined with post-processing equipment such as stacking and packaging, it can efficiently achieve the manufacturing of electrode sheets and all solid state batteries in the dry process route.

• Wet process: With high-precision battery 3D printing equipment as the core, combined with homogenization, rolling, packaging and other process equipment, it can efficiently achieve the integrated intelligent manufacturing of all solid state batteries in the wet process route.

• Equipped with an atmosphere protection system that can adapt to materials sensitive to water and oxygen.

Lithium metal all-solid-state battery small test line the whole line equipment acceptance

2024-10-12Recently, High-energy Digital Manufacturing has completed the formal delivery of another lithium metal all-solid-state ba…The small dry test line of high energy all-solid state battery is officially launched

2024-10-12At present, the all-solid-state battery that has attracted much attention is at a high speed of development and has recei…High energy production of lithium metal all-solid-state battery pilot line

2024-10-12High automation, high precision and high efficiency of the high-precision lithium metal all-solid state battery pilot lin…High energy manufacturing main business

2024-10-12➣Battery 3D printing system equipment: Innovative battery preparation process, through the battery 3D printer to achieve…